Racket basic introduction ( Part 2 ) shaft,cap, grip, end cap

Shaft

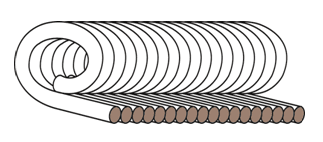

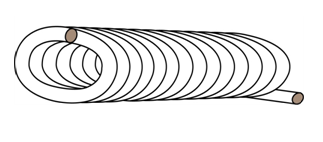

The shaft is the key part of the racket for transferring power. Shafts are made in one of two ways: one way is the traditional rolling method, like making an egg roll, and the second is the continuous (ridgeless ) coiling method also used to make golf club shafts.

Rolled type Coiled

Comparison of the strengths and weaknesses of shaft manufacturing methods

|

Manufacturing method |

Strengths |

Weaknesses |

|

Rolled type |

Low-cost, easy to make |

Uneven hardness distribution, relatively poor torque and stability |

|

Coiled type |

Even stiffness (continuous) 15% better torque resistance than rolled shaft. |

High production costs |

Generally speaking, the main point to consider when selecting a racket is the softness/stiffness of the shaft as this decides how much the shaft bends when it is subject to external force.

The usual test method involves using a universal testing machine to carry out a three point bend test; this involves placing a weight on the shaft (red arrow) so that the shape of the shaft changes (the grey broken line) and then measuring the degree of change (α); the greater the change the softer the shaft ,and vice versa.

Diagram of shaft stiffness test

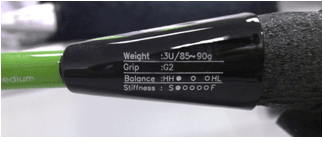

Cap

The cap links the shaft and the grip and is commonly the place where the maker will place the racket’s basic parameters, such as grip circumference, racket weight, recommended string tension, and even the stiffness of the racket.

Basic racket parameters are usually shown on the cap

Grip

The grip, or handle, is the only part of the racket that a player comes into direct contact with;the shape is irregular octagonal, a shape that offers more ways of holding the racket and shuttlecock striking angles.

The grip is usually made from wood that is quite strong and that will not easy break. In recent years, some suppliers have borrowed an idea from tennis racket manufacturing and have used a graphite strip to change racket feel and stiffness.

Hands are different in size and so grips also come in different sizes. Grip diameter is expressed as “G”;G1 suits female players or male players with small hands, G2 is suitable for the general playing population and the most common grip diameter on the market, and G3 is used by players with large hands.

Grip diameter diagram

An end cap that has been made thicker to make it easier for the thumb to secure the racket

Now you have a better understanding of the structure of a racket, let VICTOR now tell you how to choose the racket that is right for you.

( Edit by VICTOR Badminton )